Services

Project Delivery Is Our Top Priority

Our design approach

We adopt a collaborative approach with the design team to ensure that all detailed validation calculations, technical submittals and schedules are submitted for all proposed design validation/development and plant/ material selection.

GBE ensure that at the beginning of each new project a full technical review of each system is undertaken prior to the commencement of detailed coordination drawings. This protects both GBE and our clients from significant cost risk if engineering issues are not identified until late in the project life cycle.

In order to ensure these checks are robust and thorough we start our review by validating the building loads, primary plant/equipment loads against the relevant CIBSE and BSRIA guidelines as well as our experience of relevant past projects.

Dependent on our scope GBE may carry out thermal modelling and full validation of loads from first principles. Building and plant loads are confirmed and agreed with the design team.

We ensure that they are efficiently laid out whilst considering all aspects including:

- commission-ability

- expansion

- optimum circuitry and plant efficiencies

- interaction of circuits and equipment

Optimum system parameters:

- temperature selection

- LV distribution/capacity

- discrimination report

- infrastructure capacity and its parity with design loads

- life-critical supply autonomy checks

- confirmation of cables/pipe sizing etc.

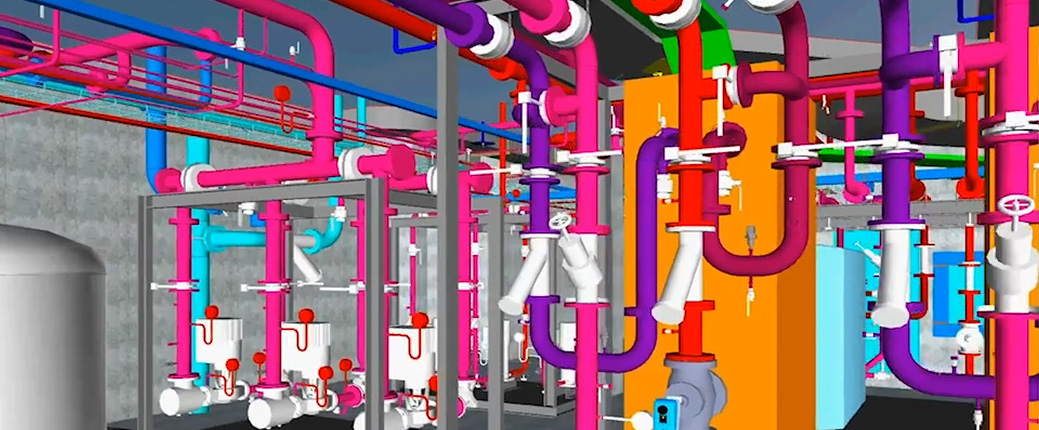

Once the schematics are finalized and plant selections have been made, GBE proceed with producing fully coordinated 3D models in line with the project prefabrication / modularization strategy.

- This is using actual plant BIM models (where available), detailed supports/bracketry etc. to produce a fully coordinated 3D model.

- Once this is finalized and agreed with the client and design team, detailed construction end sheet drawings are produced, as well as module and spool drawings for manufacture of pre-fab/modules.

- Where required, GBE are also able to, alongside the architect, generate RCP fully compliant with fire alarm and sprinkler regulations.

Mechanical and public health systems engineering

GBE have provided mechanical and public health installations on some of London’s most prestigious projects for over 18 years.

Our highly trained and experienced management teams ensure that the highest possible levels of quality are maintained on all projects undertaken.

A diverse range of capabilities

Our specialist teams offer a diverse range of services and products as demonstrated by the following:

MEPH installations

- Plantroom and plant skid construction and installation

- Modular pipework assembly and installation

- Multi-service raft assemblies incorporating full mechanical and electrical services

- Utility cupboard multi service modules

- Riser steelwork assemblies and services support frames

- Cooling tower support frames

- Gantry steelwork, stepovers and access platforms

In-house electrical systems design, project engineering & installation

At GBE our multidisciplinary teams have delivered major M&E projects across the London area.

Our electrical capability has steadily increased over the years. Developing our in-house electrical installation team and in-house electrical design and engineering capabilities, has allowed GBE to successfully complete large electrical installations across London.

One of the Largest Off-Site Fabrication Facilities in SE England

GBE Group Ltd has a fantastic facility with two fabrication units comprising 53,000 square feet of factory accommodation.

GBE’s reputation for providing top-quality fabrication and modular assemblies is second to none.

The fabrication facilities allow for the manufacture and then assembly of plant and modules at full size. A range of systems and integrity testing is undertaken before delivery by our own fleet to the site.

This ensures that GBE Group manufactures, assembles and delivers plant and modules ready for rapid installation on site.

All components are tested and traceable and structures and assemblies move through the system integrated with drawings, site scans and the CAD/BIM teams’ systems.

Delivery to the heart of London

Consolidation of our deliveries removes in excess of 600 deliveries per year from London roads.

GBE’s delivery consolidation with other suppliers leads the way in supporting London’s environmental transport policies.

GBE is accredited to various London transport schemes – like the Fleet Operator Recognition Scheme (FORS). Our logistics team offer a local, speedy and efficient delivery service for the wide range of pipework fabrication, modular and steelwork assemblies produced by our fabrication facility on the Medway City Estate in Kent.

The transport management team, using our unique barcoding system, ensure all products are fully traceable from point of production to installation on site.

GBE are also able to carry out the delivery of all major equipment using our in-house plant movement team. The diverse and flexible services that GBE offer, ensures the safe and efficient delivery of all products from small pipework fabrication to large plantroom assemblies.

Plant Handling

Using the skills and expertise to deliver exceptional projects

Battersea Power Station

Full Mechanical Electrical and Public Health apartment fit out to 308no. high end apartments as part of the Battersea Power Station redevelopment.

127 Kensington High Street

One Bishopsgate Plaza

Finsbury Tower MEP

Contract Value: £2.75m

Duration: March 2020 – January 2021